First Choose- Filament For Beginners

With the growth of FDM 3d printing. More and more people throw them into 3d printing. Choosing which type of filament becomes the 2nd thing they need to thought about. The first thing? Absolutely the 3d printer.

We put the result here: High-quality standard PLA is best for beginners.

Standard PLA

Standard PLA is currently at the top1 in all types of FDM filaments. According to market research, the monthly FDM filament sales data analysis results show that standard PLA can account for at least 70% of market sales.

So let's think about why it is so popular with desktop printer players?

1. Hardware Requairement

1) Bed Temperature: No need/50-65℃.

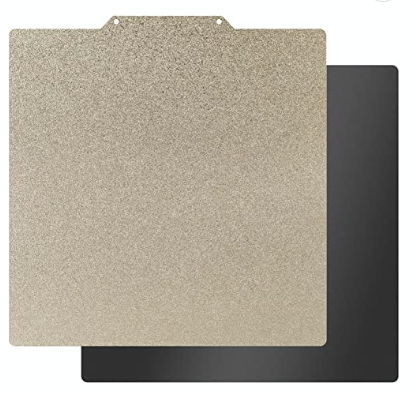

It is based on the build plate material type. Most brands of printers came with a glass build plate. Some better printers will come with the PEI sheet plate(Actually you can upgrade the glass plate to the PEI sheet). And some simple printer is limited by the price, it doesn't come with a heated bed but only provides the plate with Mask tape/Disposable plastic plate.

Don't know the build plate type? Here:

Glass Build Plate

PEI Sheet Plate

Mask Tape/Disposable plastic plate

- Mask tape/ Disposable plastic plate: No need(May cause warping)

- Glass build plate: 60-65℃

- PEI sheet plate: 50-55℃

2) Nozzle temperature: 190-220℃

For this section. There are 2 factors that need to be considered at the same time. The first factor: The best nozzle printing temperature of PLA is different among different manufacturers. Based on our testing, surveying, and many players' feedback. The best printing temperatures for standard PLA vary from manufacturer to manufacturer, but most of them are around 190-220℃.

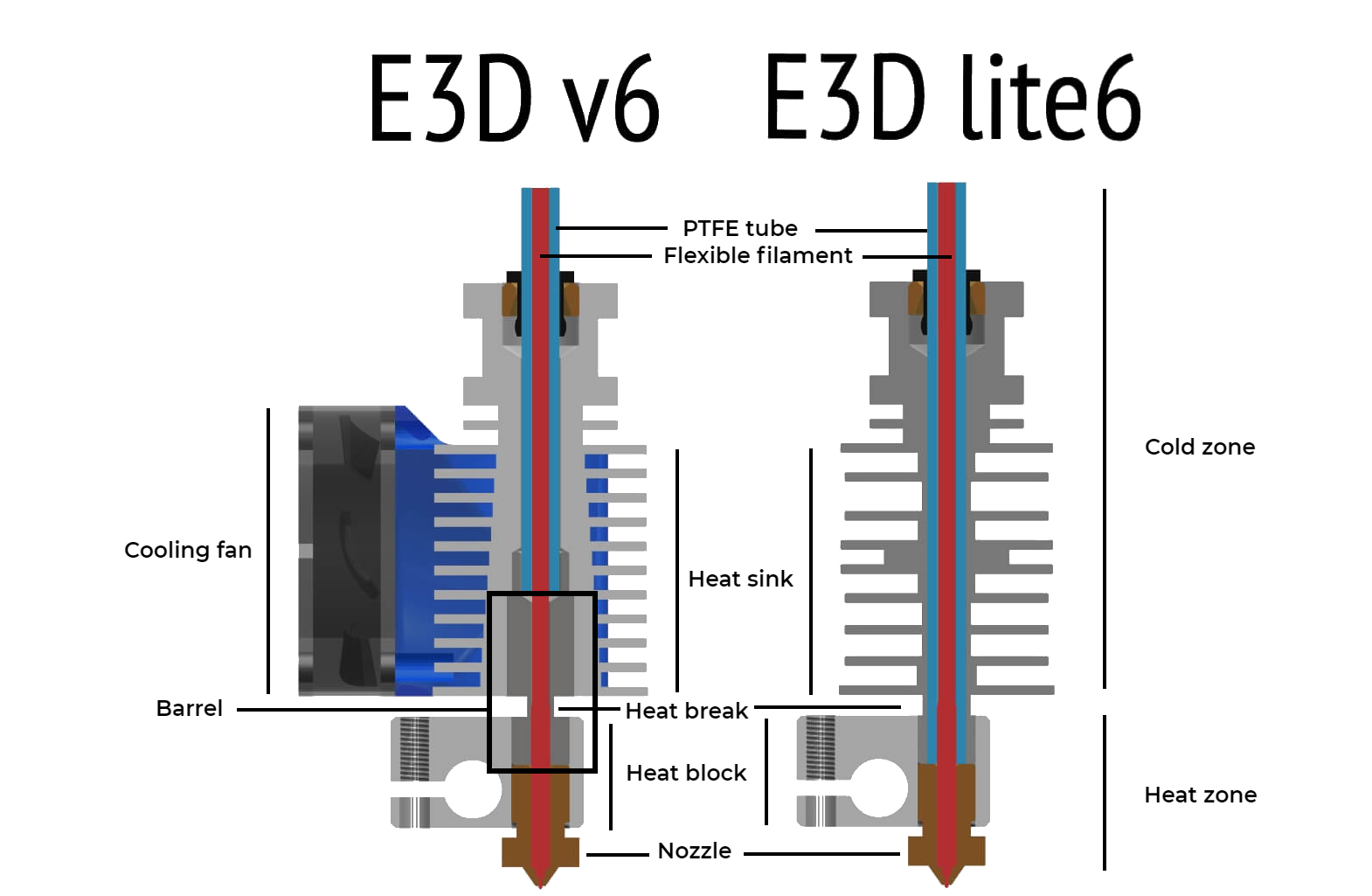

The second factor: The best printing nozzle temperature of FDM printers with different structures of the hotend is different. PTFE Hotend and All Metal Hotend are 2 structures of the hotend and we can get the different best nozzle temperature results. Of course, the clog situation is beyond this discussion.

Left side is All Metal hotend and the right side is PTFE hotend

The question is:

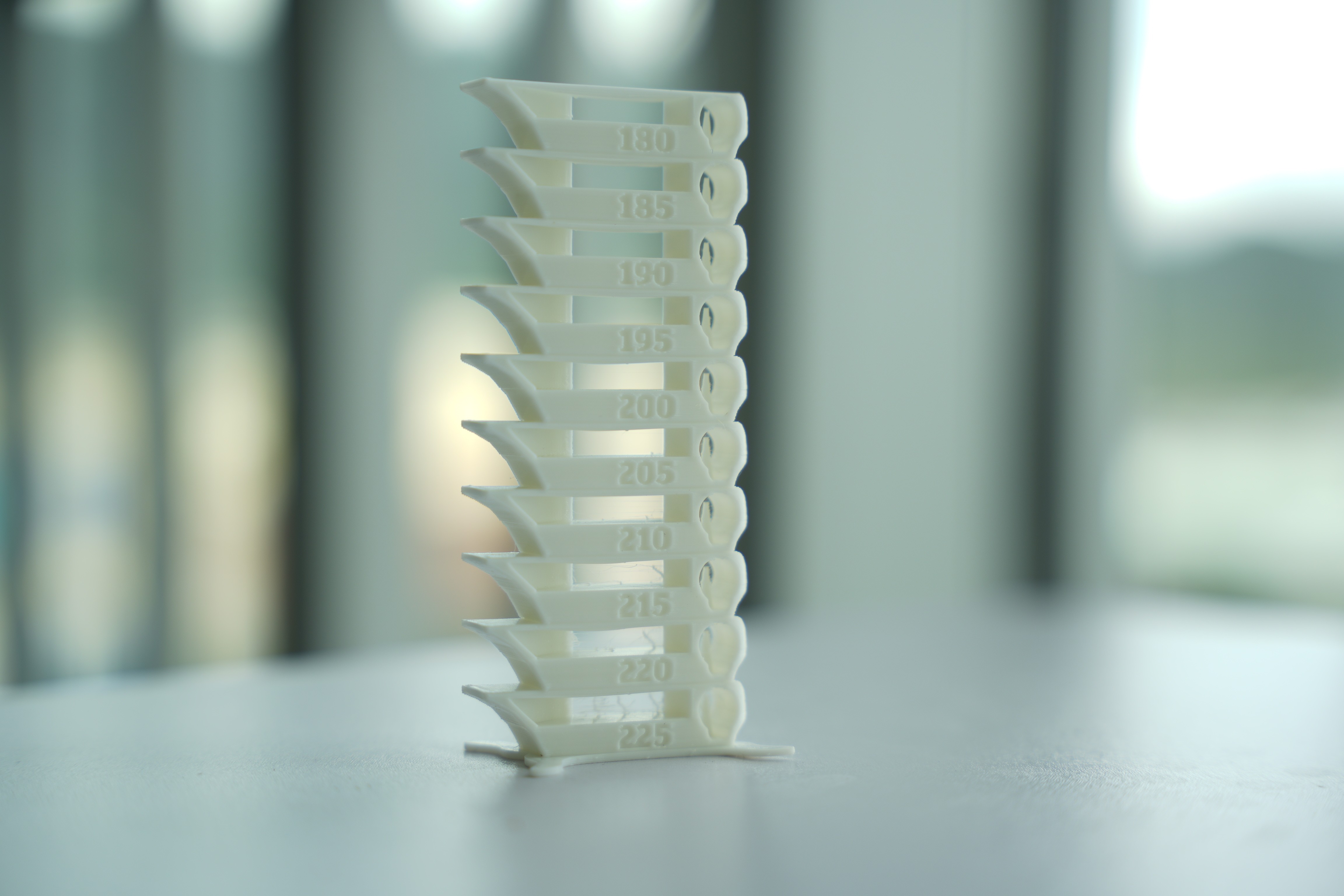

How do we know the best nozzle printing temperature (for one of our printers) for a new roll of filament?

We provide some simple test methods to get the answer we want, refer to this post

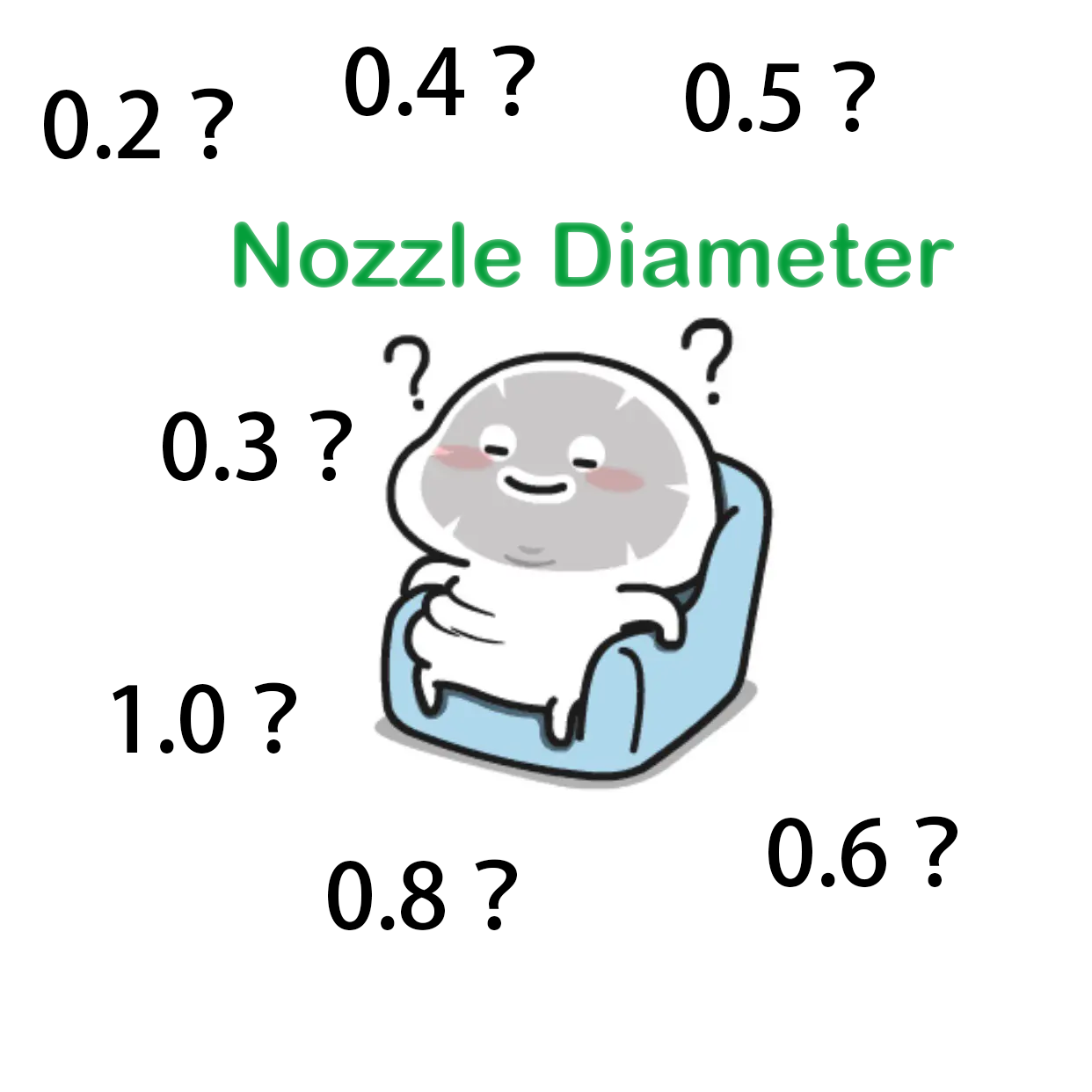

3) Nozzle diameter and material

Usually, the FDM 3d printer comes with a 0.4mm nozzle and its material is brass. Standard PLA filament is friendly with a 0.4mm brass nozzle. So you don't need to worry about this. We will talk about more info about how to choose the nozzle in another post.

2. Slicer Software Setting

1) Printing Speed

So we already have a 3d printer. The next thing is slicing the stl to get the gcode, then printing. Slicing is the same as important with the 3d printer. We are not talking about how to slice the stl at this post. We will create another post to explain the slicing. But how about the slice setting of Standard PLA?

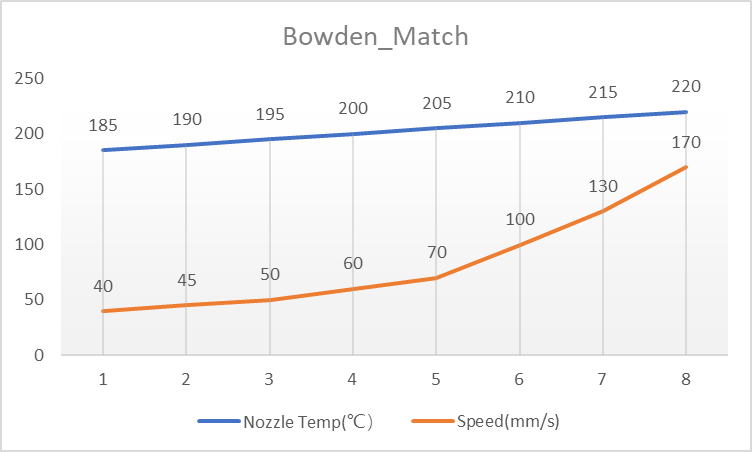

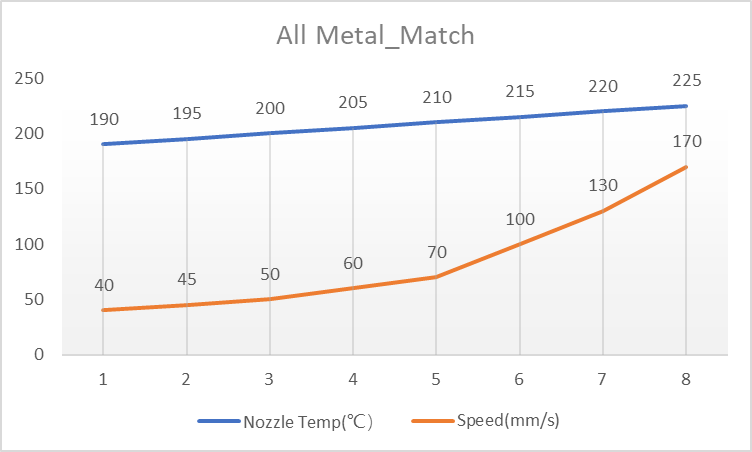

Source: MiragC

You can refer to this pic to match the temperature and printing speed.

Based on Temperature Tower Test(35mm/s, Bowden hotend)

2) Retraction Speed&Distance

Stringing problems always affect our printing effect. So the slicing applications, like Cura/Prusa Slicer/Repetier-host enabled this feature as default. Enabling retraction means when hotend crosses an empty space, the filament will be pulled back a bit by the feeder(In our experience, this action is usually advanced a bit before it crosses an empty space). Once the hotend has arrived at the next location, the filament will be pushed back out and printing resumes from the nozzle again.

Note: Before you set this setting, the best nozzle temperature setting is needed.

Retraction speed

The retraction speed determines how quickly the filament is pulled back.

- A faster retraction speed can decrease the stringing effect.

- The retraction speed is also related to the extruder motor motion acceleration, if you find no matter how adjusted the retraction speed and the result is still the same. Then you may move your attention to this point.

- But the retraction speed too high can also cause problems: The motor skips steps and the filament breaks for the gear(Around the feeder) then which causes the clog.

Therefore, you should do a test to find out the balance point for your printer. This information may help:

- Bowden extruder: 60-80mm/s.

- Direct drive extruder: 30-40mm/s.

Retraction distance

Retraction distance is probably the most critical retraction setting. If you set the incorrect distance may cause a clog and decrease the printing success percent. You can do a retraction test print to find out the correct setting for your printer. We provide our test results and experience for this as reference:

- Bowden extruder: 6-8mm

- Direct drive extruder: 0.5-1.5mm

3. Mechanical properties&Physical properties

The index of mechanical properties can be a good measure of the performance of PLA in actual use. provide us with some references.

Physical properties

- Density: 1.25-1.28g/cm3

- Melting point: 175℃

- Heated defected point: 50-55℃

Mechanical properties(Before the printing...)

- Tensile Yield Strength: 40-60 MPa

- Elongation at Yield Point: 4%-10%

- Flexural Strength: 100-150 MPa

- Flexural Modulus: 3000-4000 MPa

- Impact Strength Charpy (notched): 20-60 J/m

We can only give these index because the different brand standard PLA filament properties is not always the same. Another side: Your prints cannot reach the mechanical properties of the filament before printing. The reason may be: The method you print, the way you slice, etc.

After reading it, we found that its performance is not very strong. So we don't think you should use this material for printing your important parts.

4. Storage

Standard PLA will absorb moisture from the wet air. When you don't use it, putting it into the electric dryer box is a good idea. It can avoid the wet air affecting your filament. The dryer box can “rebirth” the wet standard PLA but the negative effects caused by wet air cannot be completely eliminated.

Therefore, you should store your filament in a moisture-free environment, like a plastic box, especially if you live in a humid environment.

Above all, it does not have high requirements on the hardware of the printer and has good adaptability to different temperatures. Even if you accidentally set the incorrect setting, there is a high probability that it can still be printed (maybe the result is not ideal). There's another big reason: it's an ECO material, which means it's biodegradable without polluting the environment. So it is the preferred filament type for beginners.