How to choose the nozzle

The nozzle is a very small part of the printer but you can't ignore it. If you select the correct nozzle then it will reduce the problem of clogging and reach your psychological expectations. Before you want to choose the nozzle, it is very important to know about them.

We will have 3 sections to explain how to choose the nozzle

Filament Classifiation | Nozzle Classifiation | Nozzle Material

Filament Classification

If we classify them as 3 types of filament.

- Regular Filament

- Abrasive Filament

- Special Abrasive Filament

Nozzle Classification

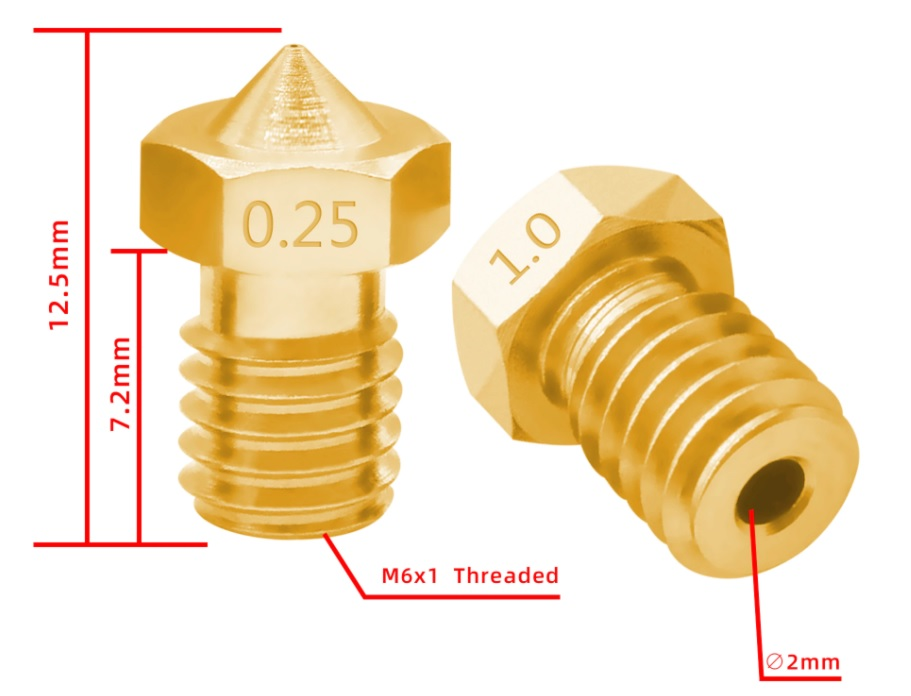

Most brands of the 3d printer came with the 0.4mm brass nozzle. It can use for printing standard PLA/standard PETG/standard TPU without problems. We classified it with:

- Filament diameter: 1.75mm/2.85mm

- Size: 0.25mm/0.3mm/0.4mm/0.5mm/0.6mm/0.8mm/1.0mm

- Thread type&Angle

- Material

- Shaft length

E3D Nozzle

When we talked about the nozzle then we can't skip the E3D V6 nozzle. The industry leader for quality hotends is E3D. They have led the development of the nozzle industry and made a lot of contributions.

E3D nozzles are compatible with many printers’ stock hotends, including those of the following:

- Prusa i3 MK2/MK3

- Ender3/CR10 Series

- Ultimaker 2+

- MakerBot Replicator 2

More printers' model didn't list because the article is limited.

MK8 Nozzle

The MK8 nozzle was a very popular nozzle model until the E3D nozzle was released. Today, there are still many manufacturers who choose to use it for their printers.

Tip: If the specifications of the MK8 and E3D threads are the same, then they can be replaced.

Nozzle Size

In fact, we do not recommend the 0.25mm size nozzle, the 0.3mm nozzle is the smallest size we should choose. We should be aware of 2 problems:

- Even though our nozzle size is 0.25mm, we still can't improve much detail due to the structure of the machine and the driver chip. Instead, we need to spend a lot of time calibrating and our printing time will increase greatly (Increased printing time means increased uncontrollable percent increased)

- The small size of the 0.25mm nozzle means that it has high-quality requirements for the filament. Of course, the filaments we produce can fully meet this requirement, but when you use them, you will find that material clogged because some type of filaments may add some kind of fiber inside.

Another side, a large size doesn't mean low details. The Prusa slic3r supports the "Arachne"feature. As we can see the large size nozzle also can give you good details.

For these types of filaments, we suggest you use the 0.6mm nozzle.

- Marble PLA

- Glow in dark PLA

- Matte PLA

- Galaxy PLA

- Wood PLA

- Metallic PLA

- Carbon fiber PLA

These filaments have added particles or fiber materials, so we recommend that you use a 0.6mm diameter nozzle (We will mention its corresponding nozzle material later)

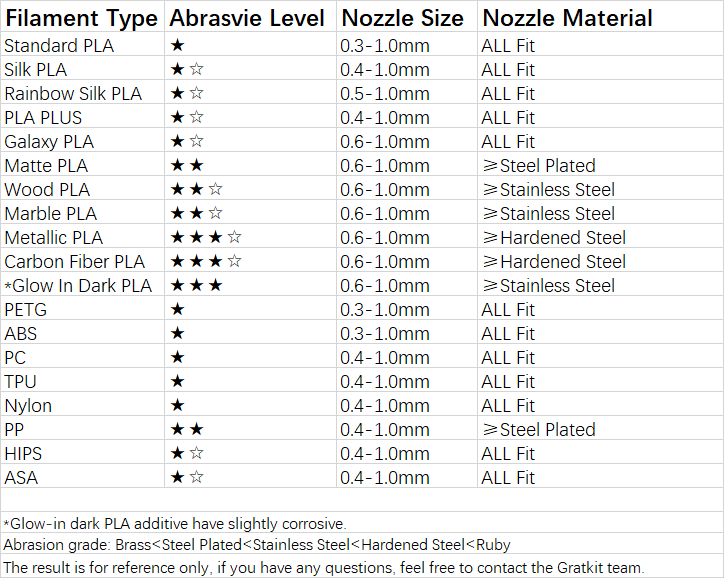

Filament Abrasion Level

Nozzle Material

Nozzles are made from a variety of metals, and you should select a nozzle made from the type of metal that matches the type of filament you want to print with. The main reason for this is fairly simple: some filaments are abrasive and will wear down certain types of metal.

Here is a list of the common metals used to make nozzles:

- Brass - The most common metal used for nozzles, brass can be used to print PLA, ABS, PETG, Nylon, TPE, TPU, PC, and most any other non-abrasive materials.

- Stainless steel - Stainless steel is ideal if you need a lead-free nozzle for FDA-approved materials or medical devices. Need to check whether the stainless steel is a food-safe-grade 304 model or not.

- Stainless Plated- Its advantage is that it has the excellent thermal conductivity of copper, and its wear resistance is also greatly improved due to electroplating. The disadvantage is that when the plating layer is worn out, it will be quickly worn away by the abrasive material.

- Hardened steel - If you want to print abrasive materials, like Carbon Fiber PLA for example, hardened steel nozzles are what you want.

- Specialty materials - Other materials, like Tungsten and Ruby, have been used to make harder nozzles that can stand up to constant abrasion. These are for printing exclusively abrasive materials, and typically cost more than the other options.

How to change the nozzle

Heat the hot end to printing temperature, or at least 200°C. Failure to heat the hot end before changing the nozzle is the most common reason for a broken nozzle.

Use a tool like an adjustable wrench or channel locks to steady the heat block, while you use a socket wrench to turn the nozzle. (E3D nozzles are 7mm, for reference)

Make sure the hot end is still hot when installing the new nozzle.