What is the PETG?

PETG and PLA are also FDA materials, so theoretically they are non-toxic and harmless. You might plan to use it for prints that come in contact with food, but we need an extra caveat: because of the pores in the print, bacteria can grow here and make it unsafe. Another point, please check carefully with the manufacturer that their additives are FDA materials.

PET AND PETG

PETG was adapted from PET, a material that was created in 1941 to use as synthetic fiber in the textile industry. In the early 1950s, PET began to be used for food packaging and, since the mid-70s, as a material for bottles. PET is still used for all of these, especially plastic bottles, and it’s the most used plastic in the world.

However, PET has disadvantages. It tends to crystalize at high temperatures, which makes it opaque and weakens its structure. It becomes frail and bubbly, making it unsuitable for 3D printing. PETG was developed to overcome these disadvantages.

PETG has a similar composition, but the difference is in how it’s chemically achieved. According to TWI Global, PET is created through esterification from glycol and terephthalic acid, resulting in a long chain of polyethylene terephthalate. In contrast, PETG is achieved by replacing the ethylene glycol with cyclohexane dimethanol, which is a larger monomer. It helps to avoid the tight-knit molecules of PET, reducing crystallization.

Material Properties

PETG is a thermoplastic polyester, meaning it can be deformed with heat, as opposed to a thermoset plastic, which can’t be deformed and just burns.

Among its positive attributes, PETG has significant chemical and heat resistance, good durability, and formability (compared to other plastics). It also has a bit of flexibility, making it suitable for applications that require impact resistance. As we mentioned above, PETG is food-safe and non-toxic.

On the negative side, PETG has a softer surface than PET, so it’s more prone to wear. That being said, it remains more durable and heat resistant than PLA.

If not treated correctly, PETG can be harmful to the environment. While some suggest PETG is recyclable, many recycling programs exclude it.

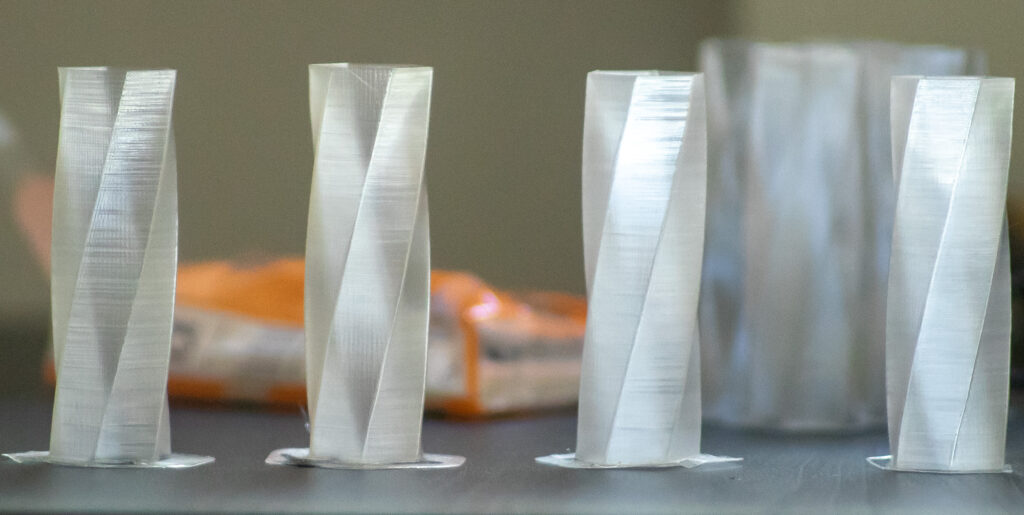

Printing Properties

PETG has similar printing settings to ABS, but it’s easier to handle. For example, PETG is mostly odorless, and printing with an enclosure isn’t necessary. Like ABS, it requires high heat.

Nozzle Temperature: 220-250℃(It should be 260℃. But most PTFE can't resist at 260℃ for a long time)

If you are using the all-metal hotend, it should be 225-255℃)

Bed temperature: 80-90℃(PEI Sheet)/85℃-95℃(Glass bed)

Printing Speed: 60-80mm/s(230℃)

Retract Speed&Length

PTFE hotend: 70mm/s+, 6mm

Direct Drive hotend: 40mm/s+, 2.5mm

PEI bed needs to set the first layer height again if you printed PLA before. Simple:

0.2mm for PLA then you need to increase it to 0.25mm to avoid it defecting your PEI. The PETG filament can be sticking PEI very strong.

Storage it

PETG is hygroscopic. If left out, it will absorb moisture from the air. This leads to all sorts of problems that mostly culminate with a disappointing failed print, so be sure you keep PETG stored in a dry environment. Try using a container or resealable bags and silicate bags.