Filament Spool? Which one is the best

If you are under printing the filament. Then this may makes you a headache: The empty filament spool when all the filament is used. Then you will get the empty filament spool. The filament spool material could be ABS, HIPS and PS, etc. And this will lead us to think of the answer to this question: How to handle the empty filament spoo-l.

On the other hand, we need to point out: A few of the filament brands will disclose the materials of the filament spool. Without this key information, it may cause filament recycling very difficult.

When you saw this pic, you may be shocked by this pic. A lot of empty filament spools are being randomly discarded. Can we find out a solution to this situation?

We think these solutions may improve this situation:

Feedback to filament brands to require them to disclose the materials of filament spool

Using the "No filament spool filament+Assemblable filament spool" this solution

Using the cardboard filament spool design

Filament spool recycle

As we mentioned above, brands should disclose this information. If we know the material of the filament plate,

We can simply sort it and then pass it through the plastic recycling mechanism. We are allowing it to be reused, which reduces the use of plastic.

However, as far as the current situation is concerned, the recycling rate of plastics is not high.

According to OECD data, in 2021, China's consumption of plastic recycling rate will be about 30%, Europe's around 23.1%, Canada's less than 10%, and the plastic recycling rate in the United States is less than 6%. This means that most part of the plastic is still discarded, which is a severe problem for the environment.

According to the actual situation, it will improve the recycling rate of waste plastic but the real effect is not expected to be high.

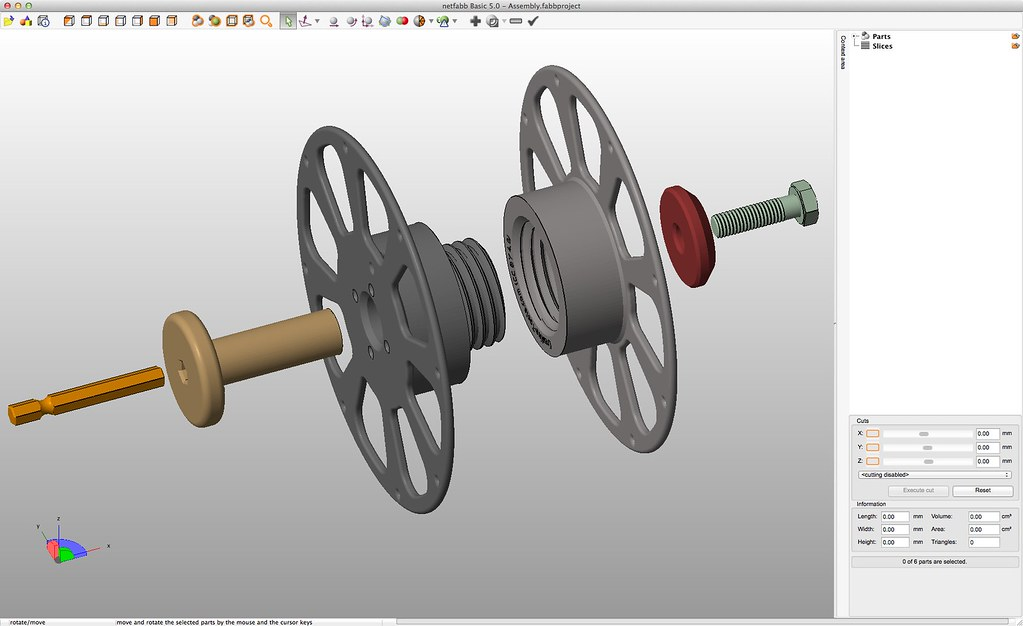

No filament spool+ Assemble filament spool solution

I think this design is fascinating, it definitely solves the recycling problem of filament dishes. Just print a filament plate in PLA and you can start creating great designs. In theory, this seems to be the case. However, there are not many users who actually buy it. Let's analyze the actual situation of users:

This cannot be your first roll of filament because you will also need a roll of filament(with a filament spool) to print an assembled filament spool.

The price, because the current design is not accepted by most people, indirectly leads to the fact that the total cost of this filament cannot be lowered. On the other hand, because of cost issues,

Manufacturers take into account the actual situation: How much of this type of filaments do we process? The answer to this question is unclear.

Other problems. Since there is no filament spool to the tight filament, when the vacuum process is performed, this process will easily cause the filament to become uneven as a whole, which may cause the filament to tangle easily and print to fail.

It is a good design absolutely but not perfect. If the brands can improve it, it's definitely the best.

Cardboard filament spool

More and more manufacturers are switching tracks, replacing the original plastic spool with cardboard. One reason for this change is that users and brands are gradually it's really valuable to start exploring how to protect our environmental measures because these things will make us better.

Cardboard spools can be easily handled, and cardboard spools are generally made of waste paper for reuse. Of course, things generally have their pros and cons.

Of course, cardboard spools also have some disadvantages:

In order to ensure that the cardboard can protect+tight the filament, the cardboard needs to be thicker to withstand greater pressure to protect the filament.

After increasing the thickness, this will easily increase the overall weight and the shipping cost will be higher than the original basis (not by much, but the price will increase)

The edge of the cardboard is not strong enough which means that the filament spool may be susceptible to moisture and cause the edge to soften

Here we need to mention the innovative design of Gratkit, we are based on the concept of ECO-Friendly and our filament is designed with cardboard spools.

Different from ordinary filament spools, we use high-density cardboard, which has a higher strength of the same thickness. Also, you can see from the image below, we did an extra treatment to its edges: we applied waterproof coating to the edges. Which added a certain strength and also ensured that slight moisture did not affect the plate and in turn, affect the filament itself.