Filament becoming brittle is a common problem, and if you're printing, maybe you've encountered this problem. If you never encountered this issue, we think this will enrich your knowledge of 3d printing. This is worth reading.

This article will discuss this problem and try to give some solutions.

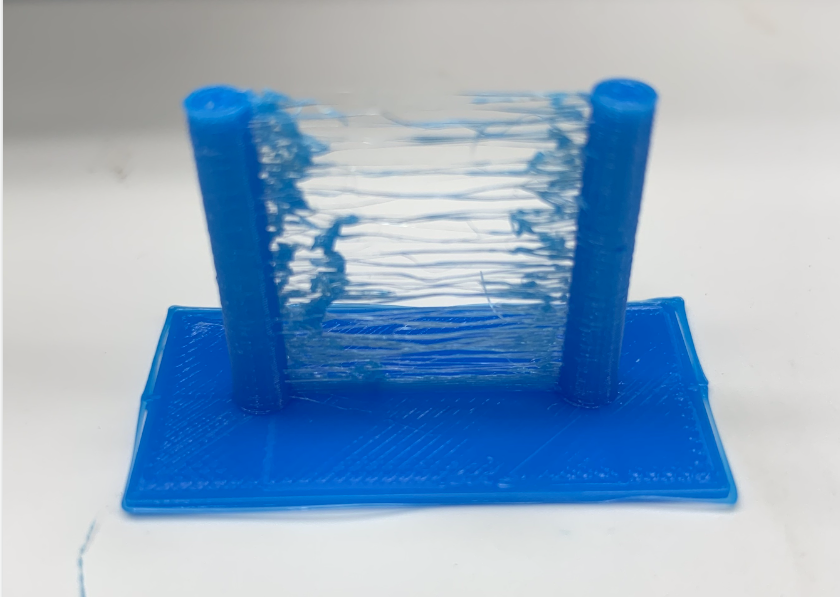

A roll of brittle PLA filament results in broken pieces reduces texture strength and causes uneven extrusion during the printing process. You may hear the popping sound when it is under printing. Also, it will increase the PLA printing stringing problem.

So how do we solve this problem? Don't worry, we may need to understand why the PLA filament becomes brittle. When we understand the reason for that, we can take corresponding measures to avoid such problems or use reasonable methods to fix them.

Why does PLA filament become brittle?

Usually, if you leave PLA filaments lying around in your warehouse without any protection, they will become brittle within a few months and decrease their mechanical properties. And if you just leave the filament in the extruder after printing, then you'll see it become brittle within a few days. Does that mean you got a bad roll of filament? The answer is a 50% chance. Another 50% is likely to be the method of storage incorrect.

Most PLA filaments contain three raw materials: PLA raw materials, tougheners, and color additives. PLA raw materials themselves are very brittle, especially when they encounter moisture, so in most cases, it is necessary to add a toughening agent to let them maintain a certain degree of toughness to improve their relatively brittle weakness.

But adding how much toughening agent is required, if you add too much toughening agent, it will easily lead to excessive stringing problems during printing. About the color additives. It has little effect on whether the filament is brittle.

Extras:

Color additives affect the polymer profile of the PLA filament, thus exhibiting different mechanical properties (But the print temperature has a greater effect on its printing, which means: The color has less effect on it).

The above is an analysis from the perspective of raw materials and production methods. But usually, after a quick inspection of the filament when you first receive it, you will find that the filament is still normal at this time. But when you forget to remove the unused filament. After a few days you will find that the part leaving the filament spool becomes easy to break (instead, the filament inside the spool is normal).

Then there are other causes: Moisture in the air and prolonged deformation (High external pressure, its performance will be attenuated).

The part of the filament that leaves the filament spool has a larger surface affected by moisture in the air and is more likely to become brittle in the same amount of time. And if an external force is applied to it during this period, it will speed up this process.

Now that we've seen why PLA filament becomes brittle, is there a solution?

How to avoid this?

Our suggestion is to refer to the following steps because prevention is more effective than repair:

- Please put the unused filament in a dry box or bag in time

GratKit’s filament will come with a dustproof bag for you. You can put the desiccant in it, then put the filament into the bag, and close the zipper bag with the zipper finally.

- If your area is relatively humid, we recommend that you regularly check the boxes and bags where the filaments are placed.

Fix brittle PLA filament

In some cases, heating the entire filament may reverse its brittleness. This is assuming that the change in its physical properties remains reversible.

Put it in the oven for 4 hours and check if the elasticity returns. When heating a full coil of filament, you need to ensure that the temperature does not exceed 45°C. You should not exceed the recommended heating temperature as the entire spool may become soft and rubbery.

Repeat the process if you feel the crispness has decreased but is not yet at the desired level. After heating the spool of filament, you can check that it is still brittle by bending the filament to see if it breaks.

If these attempts fail, you can try cutting 2-3 meters of filament from the roll. In most cases, only a small length of filament is affected, leaving the rest in pristine condition.