With manufacturers such as bambu, creality, flsun and elegoo launching fast printers one after another, it seems that a printing speed race has started in the field of 3D printing. Surprisingly, manufacturers seem to unanimously like to use 3DBenchy this model. This reminds me that I started my 3D printing journey in 2017, and my first successful print was the "3DBenchy" model.

Before popularizing fast printing, the printing speed of printers was generally 30-70mm/s. It may take you hours to get your model printed. Now it takes less than an hour to print, and you can move on to your next printing project.

When it comes to fast printing, things related to motion components and extruders need to be clarified in order to better understand fast printing.

The motion components will be covered in another post, this one will focus on the small point of filament flow in this part of the extruder.

After the printing speed is increased, the requirements for the flow of consumables are more stringent. If the parameters of the consumable flow rate cannot match the printing speed, it will directly lead to printing failure. So how do we know the flow of consumables that our speed matches? Is there a way?

Here is the formula we need to refer to:

V=Sd=Πr²d

Then assume that our printer prints at a speed of 400mm/s per second, and most of the nozzles have a diameter of 0.4mm. The extrusion required for one second is a cylinder 400mm long and 0.4mm wide.

We calculate according to the formula:

V=Sd=Πr²d=Π(0.2)²400=50.3mm³/s

It seems that we have got the answer that we need 50.3mm³/s to meet the printing speed of 400mm/s.

However, this does not take into account the actual printing situation. Our actual printing situation also needs to consider the key parameter of layer height. Generally, we will set the layer height to 0.1mm, 0.2mm, or 0.3mm. Then we need to pay attention that the filament extruded on the printing platform becomes a cuboid similar to 0.4mm x layer height x length.

Assuming that the layer height is 0.2mm, we re-enter the data into the new formula

V=LHd=400=0.4x0.2x400=32mm³/s

So we know that when the layer height is 0.2mm, the required consumable flow rate is 32mm³/s, then the 0.3mm layer height is 48mm³/s, and the 0.1mm layer height is 16mm³/s.

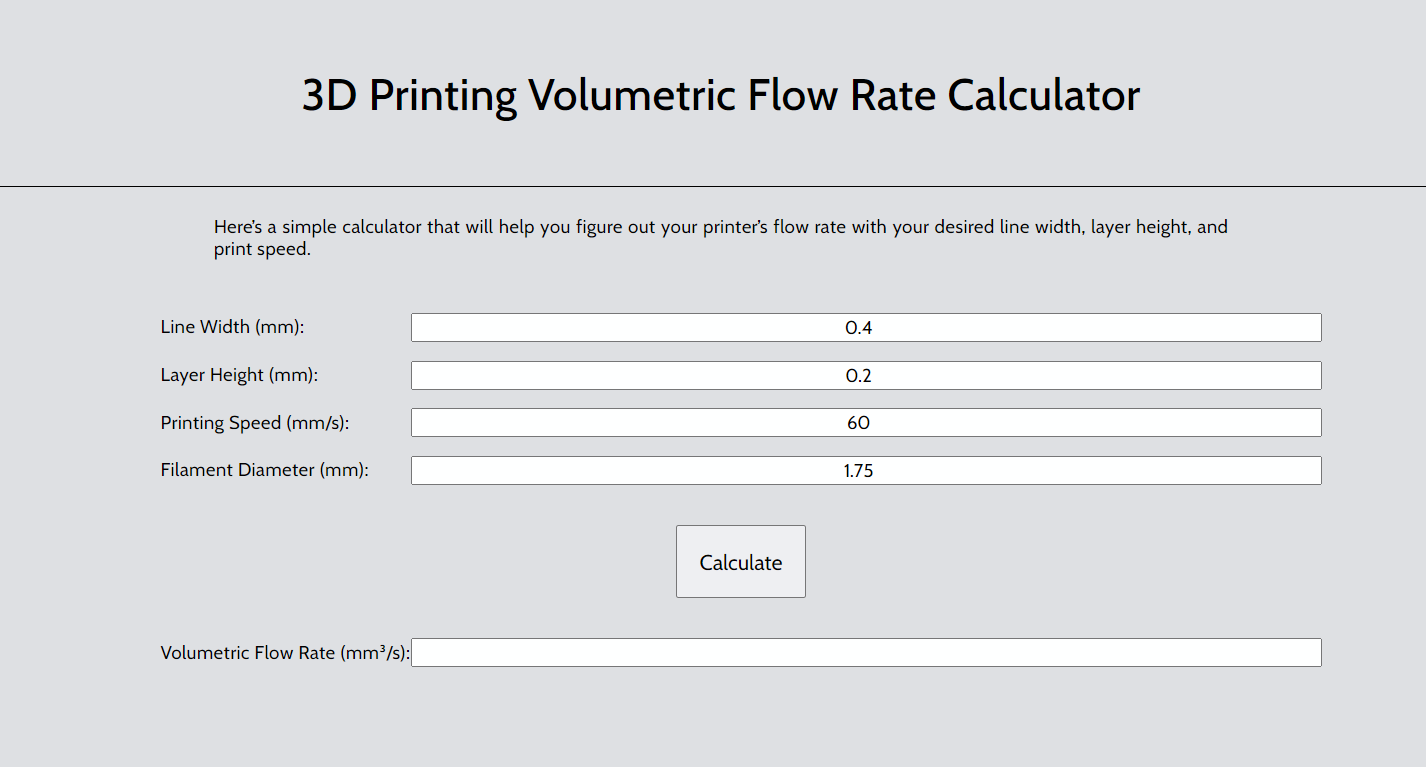

Seems hard to get the result. So we have this link:

https://www.modernmakes.ca/3d-printing/flow-rate-calculator

You just need to input the layer height then you will get the result directly 🤠

Now we know how much filament flow rate we need at the speed we want to print. And how we can know if the filament can reach this or not. Can the PLA reach this speed?

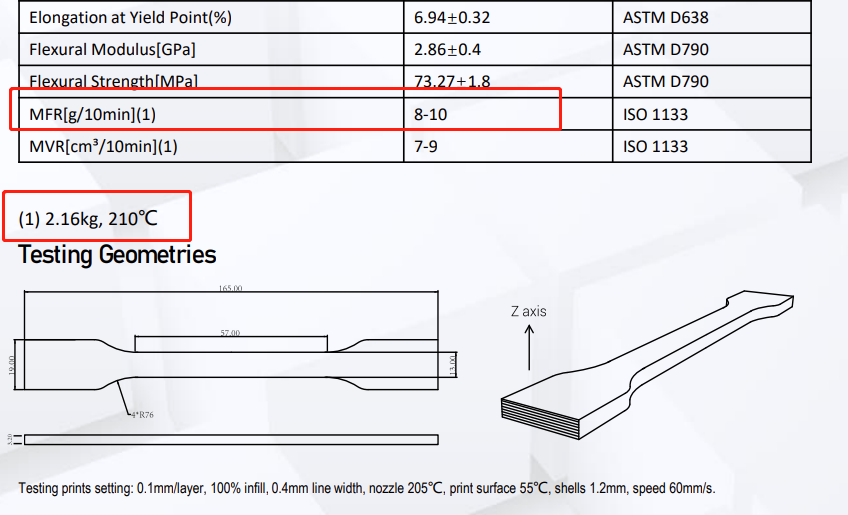

Usually, the brand of the filament will remind us of the important spec of the TDS(Technical datasheet)

One part of the spec is MFR(Melt Flow Rate). You can refer to this spec value then you know the max filament flow rate of this type filament can reach.